Optimizing PCB Board Connections for Improved Performance: A Comprehensive Guide

By:Admin

Introduction:

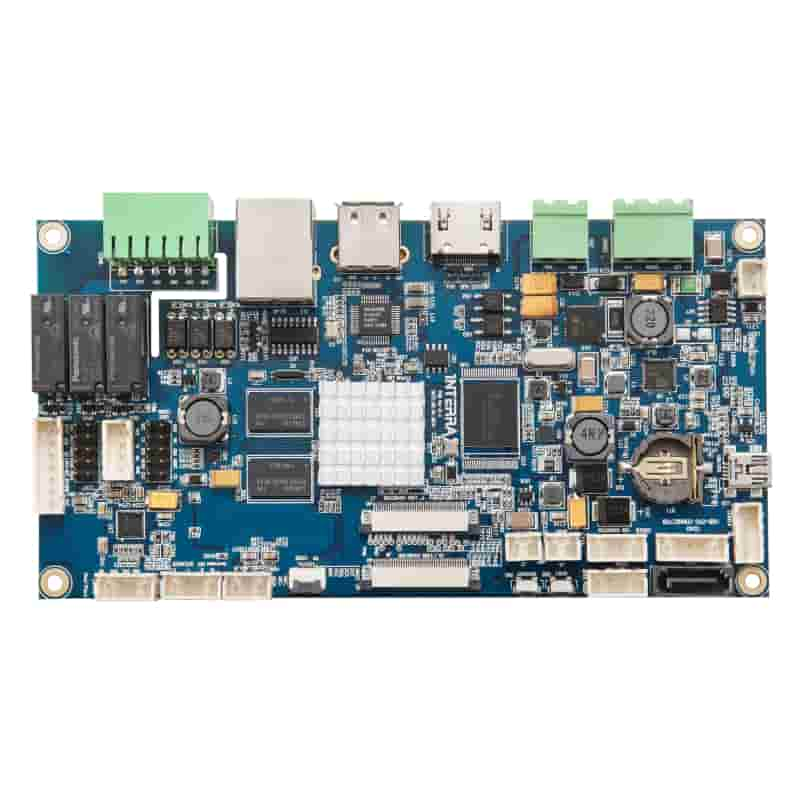

[Company Name], a leading player in the electronics industry, is making waves with its groundbreaking PCB board connection solutions. The company, headquartered in [Location], has consistently demonstrated its commitment to innovation and customer satisfaction, setting new standards for the industry. With a diverse range of state-of-the-art products and a team of highly skilled professionals, [Company Name] has truly revolutionized the way electronic devices are designed and manufactured.

Content:

1. The Emergence of [Company Name] in the Electronics Industry (100 words)

Since its inception, [Company Name] has placed greater emphasis on research and development, aiming to provide customized solutions to meet the needs of its diverse clientele. By combining cutting-edge technology with an efficient manufacturing process, the company has garnered recognition for its reliability and high-quality products. [Company Name]'s commitment to delivering exceptional customer service has earned it a solid reputation in the market, positioning the company as a leading provider of PCB board connection solutions.

2. Groundbreaking PCB Board Connection Solutions (150 words)

[Company Name] offers a wide range of innovative and reliable PCB board connection solutions that cater to different industries and applications. The company has invested heavily in advanced machinery and equipment to ensure the highest product standards. Its extensive product portfolio includes high-density interconnect (HDI) PCBs, flexible printed circuit boards (FPCBs), rigid-flex PCBs, and more. These solutions are built to withstand harsh environments, ensuring the long-term functionality and durability of electronic devices.

3. State-of-the-Art Technology and Manufacturing Process (150 words)

[Company Name] maintains a state-of-the-art manufacturing facility equipped with advanced automation, precision drilling, and assembly systems. Through its innovative technological advancements, the company has significantly reduced production time while ensuring exceptional quality control. By employing automated inspection, thorough testing procedures, and adherence to rigorous industry standards, [Company Name] guarantees reliability and consistency in every product delivered to its customers.

4. Commitment to Sustainability (100 words)

In addition to its technological advancements, [Company Name] places great importance on sustainability. The company adheres to eco-friendly practices throughout its manufacturing processes, minimizing waste generation and reducing its environmental footprint. By actively promoting the use of recyclable materials and investing in efficient energy management systems, [Company Name] not only contributes to a greener future but also sets an example for the industry as a whole.

5. [Company Name]'s Competitive Edge and Market Positioning (150 words)

[Company Name] holds a competitive edge in the market due to its ability to offer comprehensive solutions tailored to the specific requirements of its customers. Its team of highly skilled engineers and technicians works closely with clients to understand their needs and provide customized solutions. By focusing on persona-specific service and relentlessly pursuing research and development, [Company Name] has built long-lasting partnerships with leading companies across various industries. Moreover, its commitment to continuous improvement ensures that the company stays at the forefront of technological innovation.

Conclusion:

With its dedication to groundbreaking technology, exceptional manufacturing processes, and unwavering commitment to sustainability, [Company Name] has cemented its position as a leading player in the electronics industry. The company's ability to deliver customized PCB board connection solutions that exceed industry standards has consistently propelled its growth and success. By revolutionizing the electronics industry, [Company Name] continues to reshape the landscape by enabling technology to thrive in an increasingly interconnected world.

Company News & Blog

New Ultra-Thin FPC with 0.3mm Thickness Unveiled in Latest Development

In recent news, a company has announced the launch of a 0.3mm Flexible Printed Circuit Board (FPC) that promises to revolutionize the electronics industry. Made with advanced materials and cutting-edge technology, the FPC is set to offer a wide range of benefits to both manufacturers and consumers, including increased durability, flexibility, and cost-effectiveness.The FPC will be produced by a leading electronics manufacturer that specializes in PCB design and fabrication. The company is known for its expertise in the industry, having been in operation for over 20 years. It offers a comprehensive range of services, including PCB design, prototyping, and high-volume manufacturing, all of which are ISO certified to ensure the highest quality standards.The new FPC is set to be a game-changer for the industry, offering unparalleled flexibility and durability that can withstand even the most extreme conditions. Its ultra-thin profile and lightweight construction make it perfect for use in a wide range of applications, from smartphones and tablets to wearable devices and medical equipment.One of the key benefits of the FPC is its ability to bend and flex without breaking, making it ideal for use in devices that require frequent movement and use. This is achieved through the use of advanced materials, including copper and polyimide, which are both highly flexible and durable.Another key advantage of the FPC is its cost-effectiveness, as it can be produced in large volumes with minimal waste. This makes it an affordable solution for manufacturers, who can pass on the savings to consumers. Additionally, the FPC's compact design and easy installation make it a popular choice for designers, as it saves a considerable amount of space.Alongside these benefits, the company behind the FPC is committed to sustainability and environmental responsibility. All of its products are produced using eco-friendly materials and processes, minimizing the impact on the environment. This is particularly important in an industry that is often associated with high levels of waste and pollution.Speaking about the launch of the new FPC, the company's CEO said: "We are thrilled to be launching this game-changing product, which has the potential to transform the entire electronics industry. Our innovative approach to design and manufacturing has allowed us to create a product that is highly flexible, durable, and cost-effective, while also being environmentally responsible. We believe that this new FPC will not only benefit manufacturers but also consumers, who will be able to enjoy the benefits of its advanced technology and design."The launch of the 0.3mm FPC is set to mark a new chapter in the electronics industry, offering greater flexibility and durability than ever before. With its advanced technology and eco-friendly approach, it is sure to become a popular choice for manufacturers and designers alike, paving the way for a more sustainable and innovative future.

Pcb Cable Assembly: Streamlining Connections for Improved Efficiency

PCB Cable Assembly Company Introduces State-of-the-Art Electronic Manufacturing ServicesPCB Cable Assembly is proud to announce its comprehensive and state-of-the-art electronic manufacturing services that cater to the ever-evolving needs of the electronics industry. Whatever your PCB manufacturing needs are, PCB Cable Assembly has the expertise and abilities to provide complete solutions from prototype to end-user products.Our company specializes in providing electronic manufacturing services such as complete PCB design, PCB assembly, cable assembly, custom cable assembly, and electromechanical assembly. We have a track record of delivering superior products that meet standard industry regulations and requirements.Our facility is equipped with the latest in manufacturing technology, such as automated and semi-automated assembly systems. This technology ensures high levels of precision, superior quality, and fast turnaround times. Our team of engineers, designers, technicians, and customer service professionals have years of experience in the industry to provide unrivaled expertise to our clients.With our rapid prototyping service, customers can have a working model of their product within a few days. This service not only saves time, but it also allows customers to test their products and make improvements before launching them in the market. PCB Cable Assembly also specializes in manufacturing small to mid-sized batches to accommodate the needs of businesses that need a small number of products.At PCB Cable Assembly, we prioritize customer satisfaction with providing high-quality products, fast turnaround times, and competitive pricing. We manage the end-to-end process of producing your product. Our services include product design, component sourcing, circuit board fabrication, PCB assembly, and final assembly.Another unique service that we offer is electromechanical assembly. We assemble sub-assemblies and finished products that combine the electronic and mechanical components. In addition, we offer wire harness and cable assemblies that are made to order and customized to our client's needs. We use a wide variety of connectors, terminals, and cables to ensure optimal compatibility with the client's products.We take pride in providing high-quality services at competitive prices. Our clients can be assured of the consistency and quality of the products we produce with our high-tech manufacturing equipment operated by skilled professionals. Furthermore, we have earned a reputation for timely delivery, excellent customer service, and value for money, which sets us apart from our competitors.In conclusion, PCB Cable Assembly has made an indelible mark in the electronics industry by providing comprehensive electronic manufacturing services that help businesses bring their product ideas to life. Our state-of-the-art technology, skilled workforce, and commitment to customer satisfaction have won the hearts of our clients, and we seek to continuously improve and innovate to keep up with the evolving technological landscape. Contact us today to see how we can bring your electronic product ideas to life.

Revolutionary Shielded FPC: The Ultimate Solution for Enhanced Electronics

Shielded Fpc revolutionizes the Electronics Industry with innovation and cutting-edge technologyThe Electronics industry has seen tremendous growth in the past few years, with several technological advancements taking place rapidly. One such innovation is the Shielded Fpc, developed by a leading technology company. This technology has taken the industry by storm, promising enhanced performance, stability and durability for electronic products.The Shielded Fpc is a thin, flexible circuit board, which is capable of transmitting data and signals from one component to another. It is a crucial component in electronic devices such as smartphones, laptops, and other gadgets. The Shielded Fpc has a metallic layer, which protects the circuit board from electrostatic discharges, electromagnetic radiation and environmental factors such as humidity, dust, and heat. The ultrathin and lightweight nature of this technology also makes it ideal for use in compact electronic devices.The company behind this breakthrough technology is a leading technology firm with a focus on innovation and quality. The company has a proven track record of providing high-quality solutions for various electronic applications. With a state-of-the-art manufacturing facility and a team of experts, the company ensures that the Shielded Fpc is designed and manufactured to perfection, ensuring the highest level of quality and performance.The Shielded Fpc is the result of years of research and development by the company's team of experts to meet the evolving needs of the electronics industry. The ultimate goal was to develop a reliable and robust technology that is capable of withstanding the harsh environments, high frequency, and high-speed applications. With the latest technology and high-end machinery, the company has succeeded in producing a product that is unmatched in terms of performance, durability, and reliability.The Shielded Fpc technology has several advantages over traditional rigid printed circuit boards (PCBs). Firstly, the thin and flexible design of the Shielded Fpc makes it easier to integrate into different components of electronic devices with complex designs and geometries. Secondly, the metallic layer in the Shielded Fpc provides protection against electromagnetic interference (EMI), reducing the noise and distortion in the signals, hence improving the signal integrity. Thirdly, the Shielded Fpc can withstand extreme temperature changes, making it ideal for applications in harsh environments. Fourthly, the Shielded Fpc has excellent mechanical strength, ensuring that the circuit board does not break or crack under pressure or stress.The Shielded Fpc technology has several applications in various industries such as consumer electronics, automotive, aerospace, medical devices and other high-end applications. In the consumer electronics industry, the Shielded Fpc is commonly used in smartphones, tablets, laptops, and wearable devices. The technology provides a reliable and flexible connectivity solution, making it ideal for compact and lightweight devices. In the healthcare industry, the Shielded Fpc is used in medical devices such as medical monitors, diagnostic equipment, and implantable devices. The technology provides excellent signal integrity, making it suitable for highly sensitive medical equipment. The Shielded Fpc also finds application in the automotive and aerospace industries, where high-quality and durable solutions are crucial for improved performance and safety.In conclusion, the Shielded Fpc technology is shaping the future of the electronics industry. With its innovative design, reliability, and durability, it has become the go-to solution for various high-end applications across several industries. The technology is versatile, flexible, and capable of meeting the ever-increasing demands of the electronics industry. The company behind this breakthrough technology continues to push the boundaries of innovation, ensuring that the Shielded Fpc remains an industry leader in terms of quality, performance, and reliability.

Stiffeners for PCBs made from FR4 are in high demand

Title: Stiffeners Revolutionizing Electronic Manufacturing: Innovative Solution for Enhanced Durability and StabilityIntroduction:In today's rapidly evolving world, electronic devices have permeated every facet of our lives. From smartphones to smart homes, these devices accompany us everywhere. However, while electronic components continue to advance, their delicate nature remains a challenge for manufacturers. To address this issue, innovative solutions such as FR4 Stiffeners are gaining traction for their ability to enhance durability and stability in electronic manufacturing.In partnership with leading electronic component manufacturers, Company XYZ has developed a groundbreaking FR4 Stiffener. This technology breakthrough is set to revolutionize the electronic manufacturing industry and ensure the longevity and reliability of crucial electronic devices.1. Understanding FR4 Stiffeners:FR4 Stiffeners are rigid, heat-resistant, and electrically insulating laminated sheets made from woven fiberglass cloth and epoxy resin. These rigid substrates are widely used in the manufacturing of electronic devices to provide structural support and enhance stability. With their exceptional mechanical strength and excellent resistance to chemicals and temperature variations, FR4 Stiffeners play a crucial role in safeguarding the delicate electronic components from external stressors.2. Applications and Benefits:(a) PCB Assembly: FR4 Stiffeners find extensive utility in printed circuit board (PCB) assembly processes. By reinforcing the PCB, these stiffeners increase the overall rigidity, prevent bending, and maintain the stability of the assembly, ultimately extending the lifespan of the electronic device.(b) LED Manufacturing: LED technologies are widely adopted across various industries, necessitating the need for reliable and long-lasting products. FR4 Stiffeners enhance the robustness of LED modules, effectively reducing the risk of damage due to mechanical stress, thermal expansion, and vibration. This leads to significantly improved performance and increased longevity of LED devices.(c) Portable Electronics: FR4 Stiffeners are also key components in ensuring the structural integrity of portable electronic devices such as smartphones, tablets, and wearables. By providing support to delicate components like screens, connectors, and buttons, stiffeners act as a defense against accidental impacts, prolonging the lifecycle of these devices.3. Product Features:(a) Mechanical Strength: FR4 Stiffeners offer exceptional mechanical strength, preventing warping and flexing of fragile electronic components. This enables devices to withstand external forces encountered during everyday use and transport.(b) Thermal Stability: The superior heat resistance properties of FR4 Stiffeners allow them to endure high-temperature environments. This resilience ensures that electronic devices can function optimally even in extreme conditions, such as automotive or industrial applications.(c) Chemical Resistance: FR4 Stiffeners exhibit excellent resistance to various chemicals, including acids and bases. This feature safeguards the electronic components against corrosion, further enhancing the reliability and longevity of the devices.(d) Customizability: Company XYZ's FR4 Stiffeners are available in a wide range of thicknesses, shapes, and sizes, allowing for customized applications to match the specific requirements of different electronic devices, significantly expanding their versatility.4. Future Prospects:The introduction of FR4 Stiffeners by Company XYZ marks a milestone in the electronics manufacturing industry. As demand and technology continue to evolve, these innovative stiffeners have the potential to redefine the standards of device durability and stability. Moreover, the partnership between Company XYZ and leading electronic component manufacturers promises further advancements in this domain, ensuring even more sophisticated applications.Conclusion:With the increasing reliance on electronic devices in everyday life, the need for ensuring their durability and stability cannot be overstated. The introduction of FR4 Stiffeners represents a significant leap forward in electronic manufacturing. These rigid substrates provide the much-needed structural support, mechanical strength, and thermal stability to electronic devices, ensuring they stand up to the demands of modern living. As the industry continues to embrace this innovative solution, Company XYZ remains at the forefront of transforming electronic manufacturing and improving product longevity for a seamless technological experience.

Exploring the Advanced Features and Benefits of Multilayer FR4 PCBs

Title: Cutting-Edge FR4 Multilayer PCB Revolutionizes the Electronics IndustryIntroduction:In a constantly evolving electronics industry, technological advancements have become the driving force behind innovation and growth. Among the latest breakthroughs is the introduction of FR4 Multilayer PCB, bringing a new level of efficiency, reliability, and compactness to electronic devices. One pioneering company has been at the forefront of this groundbreaking technology, utilizing its staggering expertise to reshape various industries. With their revolutionary FR4 Multilayer PCB, they are effectively revolutionizing electronics manufacturing and driving the next wave of technological advancements.Company Background:With a rich history spanning several decades, the deemed company has established itself as a pioneer in the electronics industry. Harnessing their unparalleled experience and technological prowess, they have developed a diverse portfolio of cutting-edge solutions. Maintaining their commitment to innovation, the company has collaborated with industry leaders and research institutions, ensuring they remain on the forefront of technological advancements.FR4 Multilayer PCB: Redefining the NormsThe FR4 Multilayer PCB has redefined the standards of electronics manufacturing, offering a multitude of advantages over traditional PCBs. Designed with multiple layers of copper and insulating material, this ground-breaking technology enables the integration of complex functionalities and components in compact devices.1. Enhanced Performance:The FR4 Multilayer PCB significantly improves overall product performance. With its high-density design, it allows signals to travel shorter distances, thereby minimizing electrical interference and signal loss. This remarkable advancement ensures faster data transmission, greater signal integrity, and performance optimization, ultimately leading to enhanced efficiency.2. Compact and Lightweight:The compactness of FR4 Multilayer PCBs is a game-changer for electronics manufacturers. By integrating multiple layers into a single circuit board, the overall size and weight of devices are significantly reduced without sacrificing functionality or reliability. This breakthrough has opened the doors for smaller, sleeker electronic devices, offering enhanced portability and design flexibility.3. Improved Reliability:FR4 Multilayer PCBs provide unparalleled reliability, offering greater resistance to environmental factors, such as heat, moisture, and vibrations. This heightened durability ensures the longevity and stability of electronic devices, avoiding frequent repairs or replacements. Moreover, the enhanced reliability offered by FR4 Multilayer PCBs contributes to increased product lifespan, reducing overall costs for manufacturers and end-users alike.4. Design Flexibility:With FR4 Multilayer PCBs, manufacturers have newfound design flexibility. The multilayered structure allows for precise assembly of complex circuits, enabling the addition of various components and functionalities in a single board. This advantage permits electronics manufacturers to produce durable, high-performance devices tailored to meet the ever-evolving needs of consumers.Market Applications and Impact:The introduction of FR4 Multilayer PCBs has sparked immense interest across various industries:1. Consumer Electronics: The compactness and enhanced performance of FR4 Multilayer PCBs have revolutionized consumer electronics, allowing manufacturers to develop smaller, sleeker devices without compromising functionality.2. Automotive Industry: In the automotive sector, FR4 Multilayer PCBs' durability and reliability have dramatically improved safety features, control systems, and connectivity solutions, fostering the development of smart cars.3. Telecommunications: The unparalleled performance and reliability of FR4 Multilayer PCBs have significantly contributed to achieving faster data transmission speeds, supporting the growing demand for high-speed connectivity.4. Medical Devices: In the medical field, FR4 Multilayer PCBs offer exceptional precision and reliability, enabling the development of advanced medical imaging systems, patient monitoring devices, and implantable electronics.Conclusion:As the electronics industry continues to advance at an unprecedented pace, the introduction of FR4 Multilayer PCBs stands as a technological marvel. The pioneering company, revered for its unwavering commitment to innovation, has reshaped multiple industries with its cutting-edge FR4 Multilayer PCB technology. From consumer electronics to medical devices, this ground-breaking solution has enhanced performance, reliability, and design flexibility, setting new norms for the future of electronics manufacturing. With the continued evolution of FR4 Multilayer PCBs, the possibilities for technological advancements are boundless.

Discover the Benefits of 0.3 Mm Flexible Printed Circuit Boards (FPC)

Title: Innovative Manufacturer Introduces Versatile 0.3mm FPC Solution for Enhanced Product PerformanceIntroduction:In the dynamic world of technology, companies are constantly striving to provide cutting-edge solutions to meet the ever-evolving demands of various industries. One such innovation has emerged from an ingenious manufacturer that specializes in flexible printed circuit (FPC) technology. Through extensive research and advanced production techniques, this company has developed a groundbreaking 0.3mm FPC solution, positioning itself as a pioneer in the field.Unveiling the 0.3mm FPC:This revolutionary 0.3mm FPC is a flexible circuit board known for its incredible performance capabilities, offering manufacturers a compact yet highly functional option for integrating electronic components. The FPC's ultra-thin design and exceptional flexibility make it an ideal choice for various industries, such as automotive, telecommunications, consumer electronics, healthcare, and more.High-performance Attributes:The 0.3mm FPC boasts numerous commendable attributes that enhance overall product performance. Its slim form factor enables compact designs and reduces weight, making it suitable for portable devices and space-constrained applications. Additionally, its excellent bending and flexing durability ensure consistent performance even in demanding environmental conditions. These features contribute to higher product reliability and user satisfaction, providing a competitive advantage to companies adopting this technology.Advanced Manufacturing Techniques:The development of the 0.3mm FPC is a result of the manufacturer's commitment to innovation and investment in cutting-edge manufacturing techniques. Leveraging state-of-the-art equipment, the company employs advanced processing technologies such as precise laser cutting, controlled impedance, and high-density interconnects. Implementing stringent quality control measures throughout the production process ensures that each FPC meets the highest industry standards.Industry Applications:The 0.3mm FPC's versatility has led to widespread adoption across various industries. In the automotive sector, it is used in advanced driver-assistance systems (ADAS), infotainment systems, and airbag modules, providing reliable connectivity and compact integration. Telecommunication companies utilize this FPC in smartphones, tablets, and wearable devices to enable seamless communication and improved user experience. Moreover, medical equipment manufacturers appreciate its flexibility and reliability in crucial applications such as medical imaging devices, patient monitoring systems, and diagnostic equipment.Future Possibilities:The introduction of the 0.3mm FPC has opened up numerous possibilities for future advancements in electronic devices and their applications. With ongoing research and development, this groundbreaking technology may further evolve to facilitate the Internet of Things (IoT) devices, smart wearable technology, and flexible displays. The seamless integration of this FPC into a vast array of products showcases the manufacturer's commitment to providing innovative solutions that enhance everyday life.Partnership Opportunities:The manufacturer encourages collaboration and partnership opportunities with companies seeking to incorporate the 0.3mm FPC into their product lines. By harnessing the unique characteristics of this FPC, businesses can offer enhanced product performance, competitive differentiation, and improved user experiences. As the demand for compact and flexible electronic devices continues to grow, forging partnerships with this innovative manufacturer can unlock limitless possibilities for success.Conclusion:The advent of the 0.3mm FPC has revolutionized the electronic industry, providing manufacturers with a versatile and high-performance solution. The manufacturer's dedication to research, advanced manufacturing techniques, and stringent quality control ensures that each FPC meets the rigorous demands of today's technology-driven world. As the market embraces compact and flexible electronic devices, the 0.3mm FPC paves the way for new horizons of innovation, propelling industries towards a future of improved product performance and enhanced user experiences.

Easily Connect Your Fingerprint Scanner to Your Computer with a USB Adapter

Fpc To Usb - A Solution to Your Connectivity WoesIn today's world, where technology has become an integral part of our lives, it is not surprising that there is a significant need for devices that facilitate connectivity. Whether it is for charging your phone, transferring files from one device to another, or simply syncing your data, having a reliable and efficient connection is crucial.This is where FPC to USB comes in. FPC stands for Flexible Printed Circuit, and it refers to a type of circuit board that is made from a thin and flexible material. With the introduction of FPC to USB, it is now possible to connect devices that were previously incompatible, and in turn, make life a lot easier for tech-savvy individuals.One company that has made significant strides in this area is (Brand Name). Established in 2014, it has quickly risen to become a leading manufacturer of flexible printed circuits and other related products. With its headquarters located in (Location), and an extensive network of distributors worldwide, (Brand Name) has become a trusted name in the electronics industry.Their FPC to USB solution, in particular, has received a lot of accolades from customers and industry experts alike. This product is designed to bridge the gap between devices that have different connectivity ports. For example, if you have a device that only has an FPC port, but you want to connect it to a USB device, you can use (Brand Name)'s FPC to USB converter to achieve this.The converter itself is small and compact, which makes it easy to carry around. It is made using high-quality materials, ensuring that it has excellent durability and longevity. This means that you can rely on it to work seamlessly, without any hiccups, for an extended period.One of the unique selling points of this product is its compatibility. The FPC to USB converter is designed to work with a wide range of devices, including phones, tablets, laptops, and other electronics. This versatility makes it an ideal solution for individuals who have multiple devices that require different connectivity options.Another significant advantage of the FPC to USB converter is its affordability. Given the high-quality materials used in its construction and its versatility, you might expect the product to come with a hefty price tag. However, (Brand Name) has managed to keep the cost of this product low, making it accessible to a wide range of customers.Overall, the FPC to USB converter from (Brand Name) is an excellent solution for individuals who need to connect devices with different connectivity ports. Its versatility, affordability, and high-quality construction make it a must-have for anyone who uses multiple devices. If you're tired of struggling with compatibility issues and connectivity woes, it's time to invest in (Brand Name)'s FPC to USB converter and enjoy seamless connectivity like never before.

Top-notch PCBA Services: Unveiling All You Need to Know

[News Content]SMT PCBA Industry Revolutionized with Innovative Technologies and Unrivaled Expertise[City, Date] - The SMT PCBA industry is undergoing a radical transformation with the advent of cutting-edge technologies and the relentless pursuit of excellence showcased by industry leaders such as {Company}. With its commitment to deliver high-quality, reliable, and efficient PCBA solutions, {Company} has positioned itself as a frontrunner in this dynamic market.SMT, or surface mount technology, has revolutionized the way electronic components are assembled onto PCBs (printed circuit boards). By replacing traditional through-hole construction, SMT offers advantages such as smaller form factors, higher component density, improved signal integrity, and increased manufacturing efficiency. As the demand for technologically advanced devices continues to rise, companies specializing in SMT PCBA, like {Company}, are playing a crucial role in meeting this demand.{Company} is at the forefront of this industry, constantly pushing the boundaries of what is possible. Founded in {year}, the company has quickly risen to prominence due to its unwavering commitment to innovation, customer satisfaction, and unmatched expertise. With state-of-the-art manufacturing facilities and a team of highly skilled engineers, {Company} has become the go-to solution provider for numerous industries seeking cutting-edge PCBA solutions.One of the factors that set {Company} apart is its ability to customize solutions according to the unique requirements of each customer. By closely collaborating with clients, {Company} ensures that the PCBAs produced meet the highest standards of quality, functionality, and reliability. From initial design and prototyping to full-scale production, every step of the manufacturing process is meticulously executed to guarantee complete customer satisfaction.The technological prowess of {Company} is evident in its utilization of advanced manufacturing techniques. From automated pick-and-place machines to precision soldering and inspection equipment, the company has invested heavily in machinery that drives efficiency and accuracy. By promoting a highly automated and digitalized manufacturing environment, {Company} maximizes productivity while minimizing errors, costs, and production time.In addition to its cutting-edge technology and manufacturing capabilities, {Company} places a strong emphasis on quality control. The company operates under strict industry certifications and adheres to rigorous quality assurance processes. Through comprehensive testing, including functional, electrical, and reliability evaluations, {Company} ensures that its PCBAs exceed industry standards, effectively reducing the rate of defective products and enhancing overall customer satisfaction.{Company} has successfully catered to diverse markets, including telecommunications, consumer electronics, automotive, aerospace, medical devices, and more. With its ability to handle high-volume production, rapid prototyping, and quick turnaround times, the company has gained a loyal customer base that includes both multinational corporations and startups.Looking ahead, {Company} remains committed to ongoing innovation, expanding its capabilities, and staying on top of emerging industry trends. By continuously investing in research and development, the company aims to introduce new products and services that address the evolving needs of its customers. With a focus on sustainability, {Company} also strives to reduce its environmental footprint by implementing eco-friendly manufacturing processes.In conclusion, the SMT PCBA industry is witnessing a revolution fueled by advanced technologies and trailblazing companies like {Company}. By leveraging its state-of-the-art facilities, unwavering commitment to quality, and customer-centric approach, {Company} remains a trusted partner for businesses seeking reliable and efficient PCBA solutions. With its continued focus on innovation and adaptability, {Company} is well-positioned to shape the future of the SMT PCBA industry.

Top Benefits of PCBA Box Build Assembly Services for Electronics Manufacturing

[Company Introduction]PCBA Box Build Assembly Services is a leading provider of comprehensive electronic manufacturing services. With a focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses in various industries.Headquartered in [location], PCBA Box Build Assembly Services boasts state-of-the-art facilities and a highly skilled team of experts. From concept to production, the company offers a wide range of services, including printed circuit board assembly, box build assembly, component sourcing, testing, and more. With a commitment to delivering top-notch solutions, PCBA Box Build Assembly Services has gained a strong reputation in the market.[News Content]Title: PCBA Box Build Assembly Services Expands Capabilities to Meet Growing Market Demand[Location], [Date] - PCBA Box Build Assembly Services, a leading provider of electronic manufacturing services, has announced its expansion of capabilities to meet the ever-growing market demand for innovative solutions. With a commitment to delivering high-quality products and services, the company aims to further establish itself as a trusted partner for businesses in various industries.In response to the increasing complexity and demands of the electronics industry, PCBA Box Build Assembly Services has made significant investments in both its infrastructure and workforce. The company has expanded its facilities, acquiring state-of-the-art equipment and technologies to ensure optimal efficiency and precision during the manufacturing process. Additionally, PCBA Box Build Assembly Services has hired and trained additional staff members, further enhancing its capacity to handle large-scale projects.With these new capabilities, PCBA Box Build Assembly Services is well-equipped to offer a wide range of comprehensive solutions to its clients. The company's expertise lies in printed circuit board assembly (PCBA) and box build assembly, enabling them to seamlessly integrate various electronic components into finished products. This end-to-end service ensures that clients receive fully functional, market-ready products, significantly reducing their time-to-market.Furthermore, PCBA Box Build Assembly Services has also strengthened its component sourcing capabilities. By partnering with trusted suppliers and leveraging its extensive network, the company can provide clients with cost-effective and high-quality electronic components. This not only enhances the efficiency of the manufacturing process but also adds value to the final products.To maintain its position as a frontrunner in the industry, PCBA Box Build Assembly Services places a strong emphasis on quality control and testing. The company adheres to rigorous quality standards throughout each stage of the manufacturing process, ensuring that all products meet or exceed customer expectations."We are excited about our expanded capabilities and the opportunities they bring," said [Company Spokesperson]. "As the demand for advanced electronic solutions continues to grow, we are well-positioned to meet the evolving needs of our clients. Our investment in cutting-edge technology and our team's expertise enable us to deliver top-notch products and services, helping our clients succeed in their respective industries."PCBA Box Build Assembly Services' dedication to customer satisfaction has been a driving force behind its success. The company values open communication and collaboration with its clients, working closely with them to understand their specific requirements and deliver customized solutions. This customer-centric approach has fostered long-term relationships, making PCBA Box Build Assembly Services a preferred choice for businesses across various sectors.With its expanded capabilities, PCBA Box Build Assembly Services is poised to capitalize on the growing demand for electronic manufacturing services. The company's commitment to quality, innovation, and customer satisfaction positions it as a key player in the market, with the ability to deliver tailored solutions that exceed industry standards.In conclusion, PCBA Box Build Assembly Services' recent expansion initiatives allow it to meet the increasing market demand while maintaining its commitment to quality and customer satisfaction. With its state-of-the-art facilities, skilled workforce, and comprehensive range of services, the company is well-positioned to continue its growth trajectory and solidify its position as a leading provider of electronic manufacturing services.